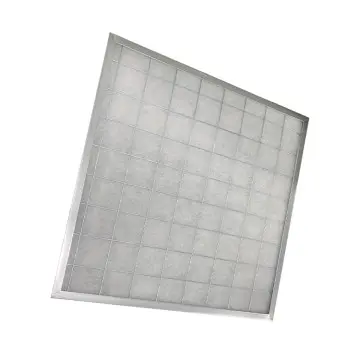

KWS Paint Mist Felt primary filter

Product Introduction

Paint mist felt filters serve as “air purifiers” in spray booths and coating workshops, specifically designed to capture tiny paint droplets suspended in the air. Simply put, they function like an oversized gas mask for the spray booth, filtering out paint mist that could harm workers' health and pollute the environment.

The core of these filters is primarily made from two materials: one is glass fiber, similar to the insulation material used in homes. It is exceptionally heat-resistant, capable of withstanding temperatures up to 260°C, and is resistant to corrosion from chemicals in paint. The other is polyester fiber, the same type of polyester fiber used in clothing. It is relatively low-cost but has slightly lower heat resistance. These fibers aren't simply layered together. Instead, they undergo a specialized “needle-punching” process, much like making a quilt, to form a fluffy three-dimensional structure. This design maximizes paint mist capture while maintaining efficient airflow.

To enhance this “mask's” performance, engineers added several “superpowers”: First, a special adhesive (epoxy or acrylic resin) is applied, much like setting spray on a sweater, making the fibers more durable and resistant to fraying. Second, fire-retardant materials are incorporated, most commonly aluminum hydroxide, ensuring it won't ignite if exposed to sparks. Finally, it undergoes waterproof and oil-repellent treatment, similar to applying a waterproof coating to a rain jacket, preventing paint from clogging the fibers.

This filter is ingeniously designed like a “three-layer sandwich”: the outermost layer has larger pores to trap coarse paint particles; the middle layer has medium-sized pores; and the innermost layer has the smallest pores to capture fine paint mist. Some premium models also “charge” the fibers (electret process), much like using static electricity to attract paper scraps, boosting paint mist capture efficiency several times over. This is especially effective for trapping particles between 0.3 and 10 microns.

For water curtain spray booths, filters require special waterproof coatings—similar to waterproofing an umbrella. In such environments, filters frequently encounter water, and untreated ones deteriorate rapidly. The latest models are testing “nanomaterial” versions, akin to wrapping filters in denser mesh stockings. These can be washed and reused like rags, offering both environmental benefits and cost savings.

Typically, these filters require replacement every 2-3 months. Just as face masks become clogged with prolonged use, filters eventually fill with paint residue, impairing airflow efficiency. Factories must distinguish between solvent-based and water-based paint environments during selection—much like choosing shoes for rainy versus sunny weather. Solvent-based environments demand high solvent resistance, while water-based settings prioritize moisture resistance.

Beyond paint type, operating temperature is crucial. Standard polyester fiber filters withstand max temperatures around 130°C (266°F). Above this threshold, opt for glass fiber filters. Filter thickness and density also matter—similar to assessing down-fill weight in jackets. The technical term is “grammage,” typically ranging from 80-200 grams per square meter. Thinner filters compromise filtration efficiency, while excessively thick ones hinder airflow.

Leading brands like AAF and Camfil continuously refine their products. They balance filtration efficiency and air resistance by adjusting fiber diameter (1-10 microns) and arrangement—akin to modifying mesh size and weave patterns in fishing nets. Current research focuses on developing washable, reusable filters, similar to modern reusable coffee filters, offering both environmental and economic benefits.

For spray booths, selecting the right paint mist filter is especially critical. A good filter not only protects worker health but also enhances spray quality by preventing paint mist from settling on freshly coated parts and causing defects. It also reduces environmental pollution by ensuring cleaner exhaust air. So don't underestimate this seemingly simple “cloth”—in the coating industry, it's an indispensable “environmental guardian”!

Product Characteristics

1.The paint mist felt is manufactured from fine glass fibers into a progressive structure, with increasing density from the air inlet to the air outlet. This design facilitates the penetration of paint dust and other particles into the filter media, enhancing its adsorption capacity.

2.Paint mist felt captures excess paint from spray systems, preventing paint splatters on equipment, protecting sprayed surfaces from damage, and safeguarding the surrounding environment. Constructed from high-strength continuous monofilament glass fibers in a gradient structure, it achieves high capture efficiency and excellent paint mist isolation.

Technical Parameter

|

NAME |

Size |

Rated airflow |

efficiency |

initial resistance |

Suggested ultimate resistance |

|

KWS-009 |

595*595*21 |

3200m³/h |

G4(35%) |

≦75Pa |

≦150Pa |

|

KWS-010 |

295*595*21 |

1200m³/h |

G4(35%) |

≦75Pa |

≦150Pa |

Applications

Generally applicable to dry spray booths, automotive, furniture, and mechanical component dry painting systems, as well as workshop paint mist filtration or kitchen fume filtration.